Laserís

For more advanced design, you can use Photoshop, CorelDRAW or AutoCAD. You can also import files in DXF, DXF, PLT and BMP file formats.

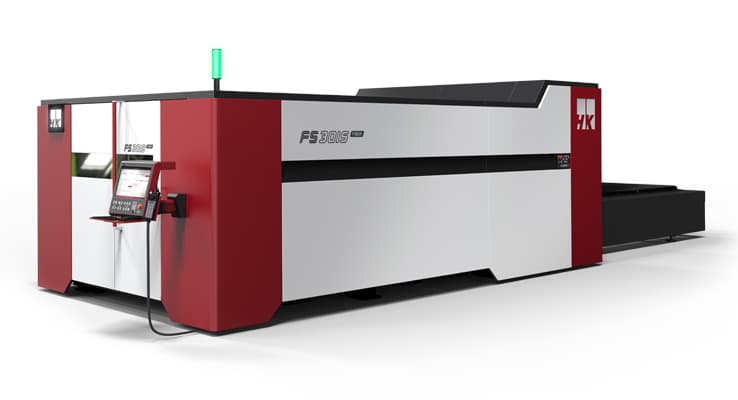

Fiber lasers are solid-state lasers used widely in laser marking and engraving machines. The major difference between a fiber laser and a CO2 laser lies in their ability to laser cut sheet metal.