Can a fiber laser cut rubber

You can access the software interface by entering your IP address in the address bar of the browser.

Boss Laser sends FM-Desktop pre-assembled. They also provide on-location technical support for their customers.

Plasma, on the other side, can efficiently cut any metal up to 80mm thick and 3 inches in diameter. When cutting thicker materials, plasma can begin cutting much faster than laser.

RetinaEngrave V3.0 can import file types including PDF, SVG JPG, BMP and others from any CAD software.

With the addition of a galvo head, they can also work at a very high speed. Galvo heads are typically used in portable laser engravers.

FM-Desktop is capable of engraving on acrylic, plastics brick, PVC granite, marble, tile and silver as well as steel, brass, brass, and Titanium.

You can access the software interface by entering your IP address in the address bar of the browser.

Boss Laser sends FM-Desktop pre-assembled. They also provide on-location technical support for their customers.

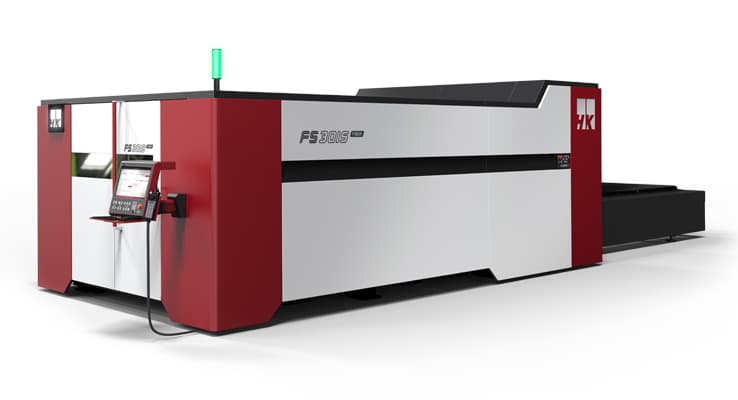

Dual-purpose fiber laser cutting machine is a commercial laser cutter system with dual functions to cut sheet metals, metal plates, metal tube, and metal pipes of steel, aluminum, alloy, titanium, copper, brass, iron, and other metal materials.

LaserWorks or RDWork software is used to control the machine. These software can be downloaded free of charge from the respective websites.

It will have the recommended speed and power rates for aluminum, steel, black acrylic, lexan, leather, granite, and more.

Keep all of your production lines flowing in the same direction: out the door and into your customers� hands.

Fiber lasers have a small focal point, so using them to cut thick materials will be impractical. In such cases, a CO2 laser is the best option.

Gulf States Saw & Machine Co. (FM1212-50S) can engrave acrylics, brick, granite and marble, tile as well as aluminum, gold, silver stainless steel, brass or titanium.

To expand the engraving area, longer focal length lenses can be used. These lenses require high concentrated power and are taller.

Fiber laser machines are better at cutting thin metals than other types of cutting machines. A fiber laser machine is capable of cutting thin metals up to 25mm (or 1 inch). Fiber lasers then start to cut metal less efficiently. To cut ticker metals larger than 25mm or 1 in., you would require a high power laser, which will cost you a lot more.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.