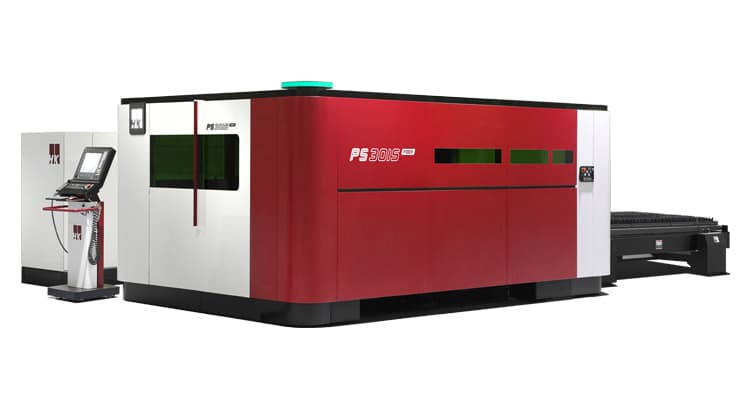

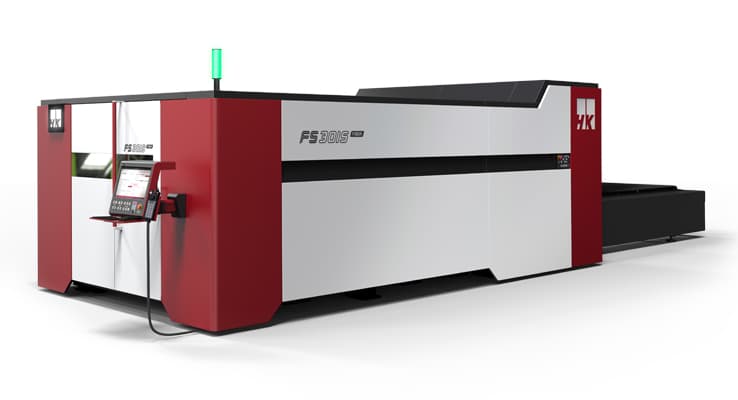

Laser Cutting

Fiber laser cutter is a type of CNC laser metal cutting system with high quality, high speed, high precision and high efficiency, which is designed for all types of metal cutting, as well as your good metal working partner. It is equipped with different laser powers (1000W to 40000W) for cutting sheet metals and metal tubes of carbon steel, stainless steel, electrical steel, tool steel, galvanized steel, mild steel, aluminum zinc plate, aluminum alloy, aluminum, titanium alloy, brass, copper, iron, and more metals with different thicknesses.

If the fiber lasers have enough power, they can cut through reflective substances. They can cut any kind of metal, provided they have enough power. They will be limited in the thickness that they can cut.