How is fiber laser produced

FM-Desktop allows for optional marking areas extensions. You can make it as large as 7.87" x 7.87", or 11.81"x 11.87".

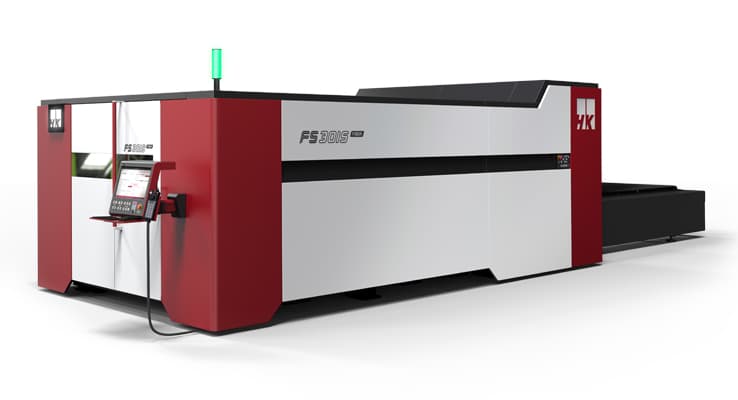

High speed IPG fiber laser cutter is type of high power laser metal cutting machine with 12000W power supply for commercial use of thick metal fabrication including stainless steel, carbon steel, mild steel, tool steel, brass, copper, aluminum, alloy, and rare metals in industrial manufacturing.