Laser Beam

Boss Laser provides pre-assembled FM-Desktops. They also offer on-site technical support to their customers.

There is not much of an upgrade option available once you purchase MCWlaser PRO, but you can customize it while purchasing.

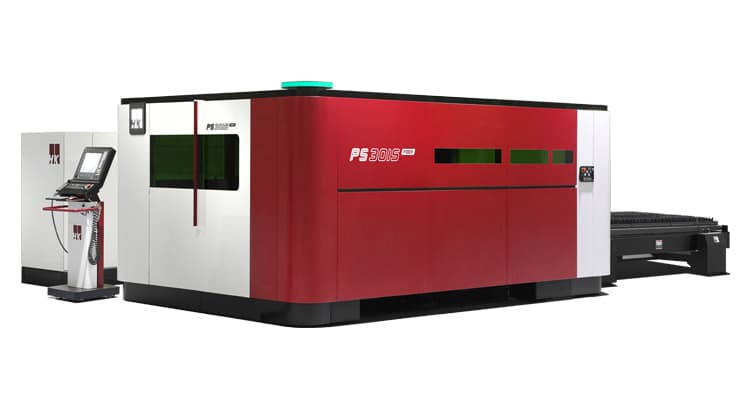

Delivering precise and consistent cutting for metal, Fiber Lasers from Gulf States Saw & Machine Co., allow you to drastically improve production and quality at the same time.

254mm, 330mm, and 420mm lenses require FSL Muse Pandora to operate in an open setup. Then only the laser can be effectively focused on the work material.

1. It has higher electro-optical conversion efficiency, which is more than 30%. The low-power laser machine has no need of a chiller. The air cooling will greatly save power consumption during operation, save costs, and achieve the highest manufacturing efficiency, 2. It only requires electrical energy during operation without additional gas, which has the lowest operation and maintenance costs, 3. It adopts semiconductor modular and redundant design. There is no optical lens in the resonant cavity, no start-up time, and it has the advantages of no adjustment, maintenance, and high stability. It reduces the cost of accessories and maintenance time, 4. The fiber laser wavelength is 1.064 microns, which makes the laser beam with high quality and high power density. It is very conducive to the absorption of metal materials, 5. The optical transmission of the whole machine is through optical fiber, no complicated light guide system such as reflecting mirror is needed, the optical path is simple, the structure is stable, and the external optical path is maintenance-free., 6. The cutting head contains a protective lens, which makes the consumption of expensive consumables such as focusing lenses extremely small, 7. The light is exported through the optical fiber, which makes the design of the mechanical system very simple, and it is very easy to integrate with the robot or multi-dimensional workbench, 8. After the laser is added with the optical shutter, it can be multi-machine, split through the optical fiber, divided into multiple channels and work simultaneously, easy to expand the function, easy and simple to upgrade.

FSL Mule Pandora must operate in an open configuration for lenses 254mm, 330mm, and 420mm. Only then can laser beams be focused onto the work material.

Boss Laser provides pre-assembled FM-Desktops. They also offer on-site technical support to their customers.

There is not much of an upgrade option available once you purchase MCWlaser PRO, but you can customize it while purchasing.

Plasma can cut any metal that is conductive. This includes reflective metals like aluminum, copper, or brass, which laser machines can't cut.

Fiber lasers are widely used for engraving on metals as they can engrave more effectively than generic CO2 lasers.

LaserWorks, RDWork, or LaserWorks software control the machine. Download them from their respective websites.

Are you trying to find the right Fiber Laser cutting machine for your needs? Get in touch with our team to find out more about our tools and how they can create anything you envision.

Raycus 50W fibre laser can engrave on stainless steel at a angle of 90 degrees. This laser uses 100% of its power.

Make sure you buy safety glasses that block the laser light of 1064 nm when buying safety glasses for this machine.

Fiber lasers are revolutionizing laser metal cutting industries with their low maintenance costs, high cutting efficiency and lower cost.

Laser cuts metal by using light. To be able to cut and pierce metal, light is concentrated at a single point. You can think of a magnifying lens that can be used for focusing sunlight onto a single point to burn it. This is how cutting with light works.

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Maximum material cutting thicknesses by 1000W fiber laser cutting machine: Carbon steel has a maximum thickness of 10mm; stainless steel has a maximum thickness of 5mm; aluminum plate has a maximum thickness of 3mm; and copper plate has a maximum thickness of 3mm.

Compressed air, nitrogen, oxygen, and argon are the four primary types of assist gas for fiber laser machines.