How is laser cutting rate calculated

Fiber lasers use solid-state lasers extensively in laser engraving and marking machines. The difference between a Fiber laser and a Co2 laser is in their ability laser cut sheet metal.

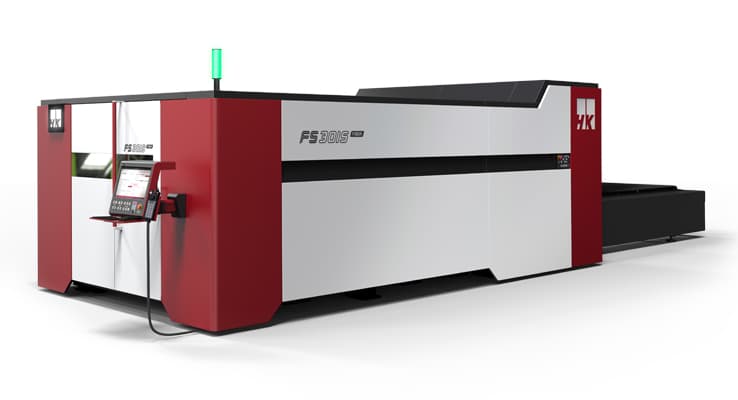

CNC metal pipe laser cutting machine with automatic feeding system for loading & unloading can meet round tube, square tube, rectangular tube, flat tube, flange beam, channel beam, U-tube, and all types of shaped tubes and pipes cutting.