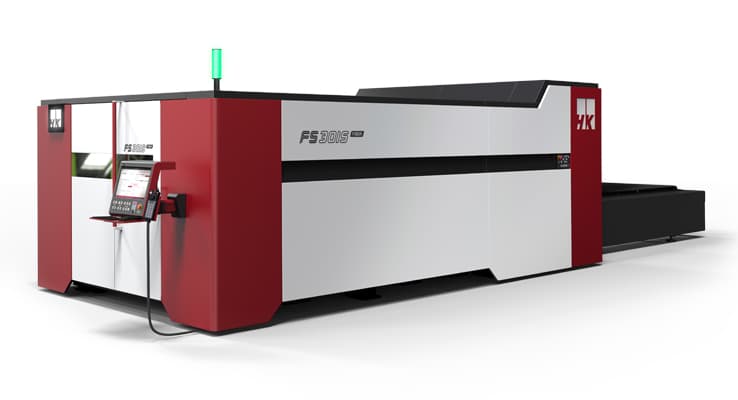

Fiber Laser Machine China

If you�re cutting very thick metals mostly, and they don�t need to be precisely cut, then plasma might be a better choice.

Fiber lasers on the other hand can cut through reflective materials if the have enough power. They can pretty much cut through any kind of metal with enough power. They will only be limited by how thick they can cut.