Handheld

They can import different file formats including DXF, BMP, DXF or AI.

The laser source is at the heart of any fiber laser. A fiber laser does not use any gaseous medium like a CO2 one.

So, if your metal cuts need to be precise, then you need a laser cutter. If you just need to cut simple shapes, and thick ones, then a plasma laser should be alright.

Raycus laser, a popular laser source brand, is used by many laser cutters and engraver companies. Raycus is often mentioned in the catalogs for different laser manufacturers. This means that all these machines are equipped with a Raycus Fiber Laser Technologies Co. Ltd. Laser source.

Just know that the running cost of plasma is lower than laser. In general, it cost about 15/hr to run plasma cutting machines. It takes about 20/hr to run a laser machine.

MCWlaser Pro is intended to be used on metals such as steel or stainless steel, silver or copper, alloy, aluminium, etc.

They can import different file formats including DXF, BMP, DXF or AI.

The laser source is at the heart of any fiber laser. A fiber laser does not use any gaseous medium like a CO2 one.

A fiber laser has eliminated the need to align beam paths and mirrors with optical fibers.

Fiber lasers can be used in laser engraving and laser marking machines. A fiber laser is able to laser cut sheet metal, which is the main difference between it and a CO2 laser.

Amazon doesn't offer a return policy. But, they will provide a 30-day replacement guarantee if you buy through Amazon.

The laser beam is then projected onto the work materials using focus lenses.

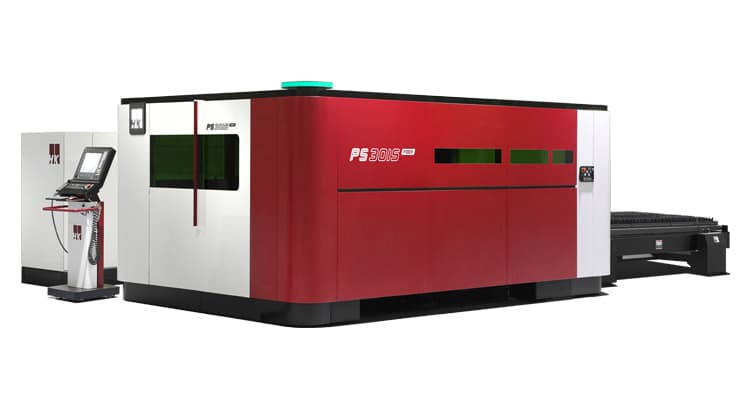

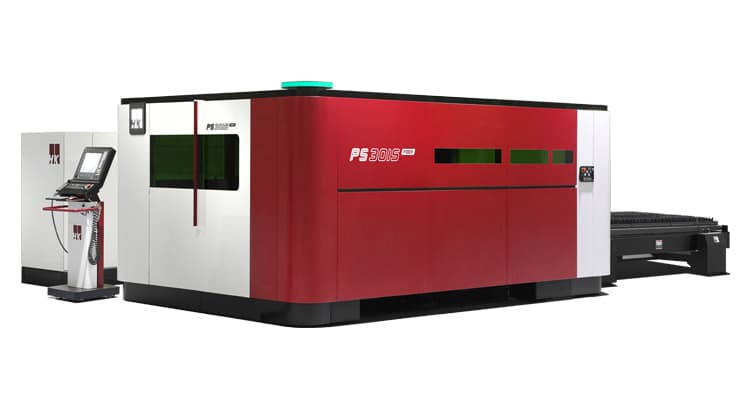

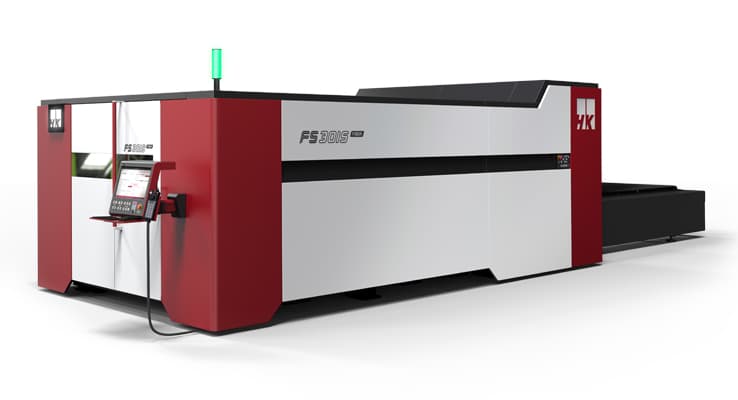

A large-sized fiber laser that brings fine, high-precision processing to projects of nearly any size.

It has a motorized entrance. It is compatible with FSL Muse Pandora on a desktop.

A special type of fiber laser known as MOPA fiber laser, provides greater control over pulse width and frequency parameters to produce color laser engravings on metals.

Raycus 50W Fiber Laser can be used to etch and mark aluminum at 90 degrees angles. It uses 100% of the laser's power.

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

The wavelength is the primary distinction that determines the types of materials that each laser can process. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have many advantages over CO2 lasers in general.

What Materials Can Be Cut With A Fiber Laser? A fiber laser cutting machine can cut sheet metal such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Fiber lasers outperform CO2 lasers in cutting reflective materials.