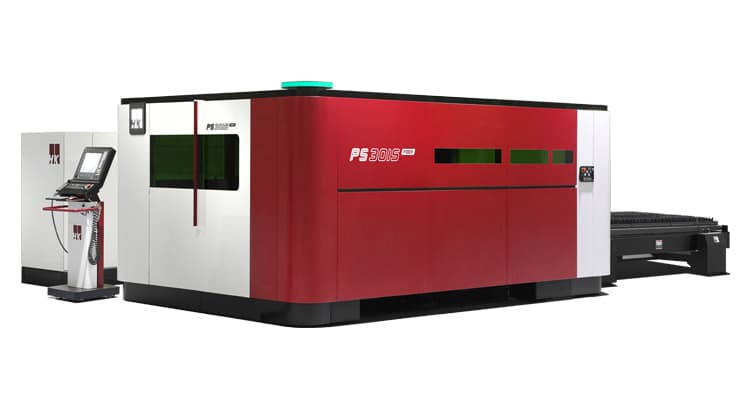

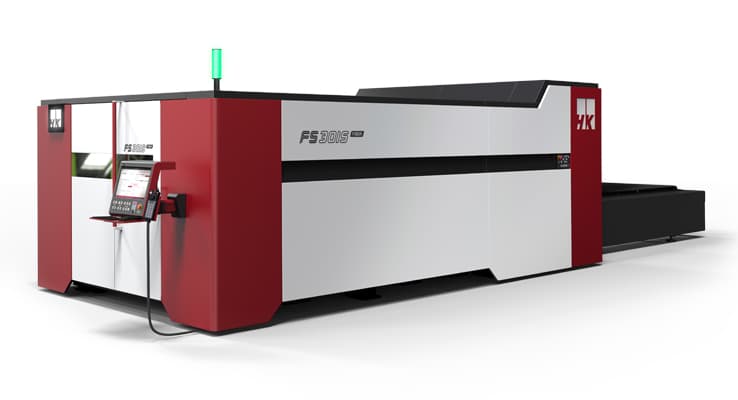

Fiber Laser Cutting Machine Trumpf

�This investment enables us to fabricate parts like we have never been able to before. We can now offer companies prototyping through high-volume production.�

Since the refrigeration compressor is sensitive to the power supply voltage, the standard working voltage is 200 ~ 250V (100 ~ 130V for 110V models). If you really need a wider operating voltage range, you can customize it separately.