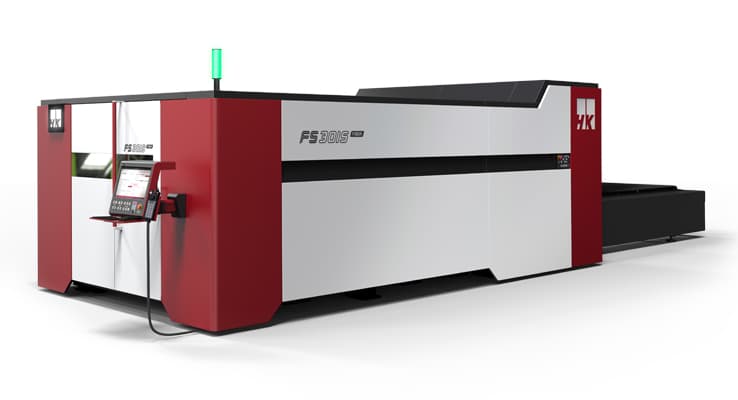

Fiber Laser Machine Kit

The laser module can engrave with a repeatable precision of +-0.00039" and a life expectancy of 100,000+ hours.

Fabrication software solutions to manage and maximize your machinery investment�seamlessly, effectively, and automatically.