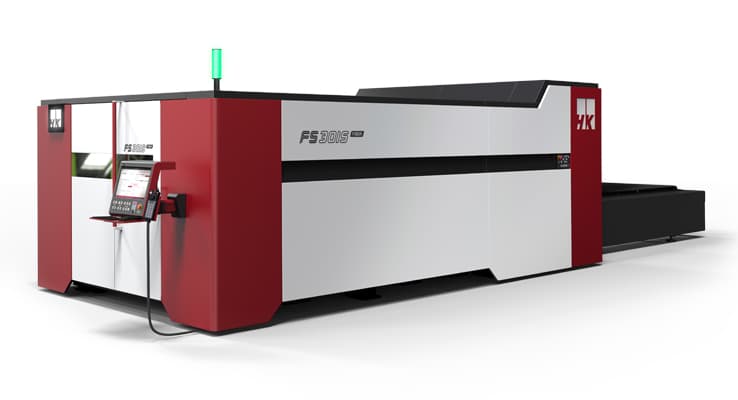

Fiber Laser Machines

Fiber lasers use high-power laser diodes to stimulate active medium and pump optical fiber with laser light.

FSL Muse Pandora can now be upgraded by adding a rotary and expanded Z-travel, fume extractions, and special focus lenses.