Applications

You can reach the software interface by entering the IP address of your computer in the browser's Address Bar.

FM-Desktop can engrave on acrylic, plastics, brick, PVC, granite, marble, tile, aluminum, silver, steel, brass, and titanium.

Fiber lasers are limited in their focal point. This makes it difficult to use them to cut thicker materials. A CO2 laser is the best choice in such situations.

A fiber laser is the best choice to laser-cut/engrave aluminum, brass, and other metal pieces.

With plasma, you usually have to finish the cut with scraping or shaving because there�s leftover residue like dross.

All types of materials can be cut by laser machines. It all depends on the type of laser machine that you have. The CO2 laser machine cannot cut through reflective metals such as aluminum, copper, or brass. They can, however, cut through non-metallic materials such as wood and plastic.

You can reach the software interface by entering the IP address of your computer in the browser's Address Bar.

FM-Desktop can engrave on acrylic, plastics, brick, PVC, granite, marble, tile, aluminum, silver, steel, brass, and titanium.

Auto-focus automatically adjusts laser head position on the Z-axis based on data received from the 3D cam.

�It's mind-blowing. It just works. It�s almost like you have to pinch yourself because it�s just that fast,� he said. �It�s cutting four to 10 times faster than a CO2, and it�s using less electricity.�

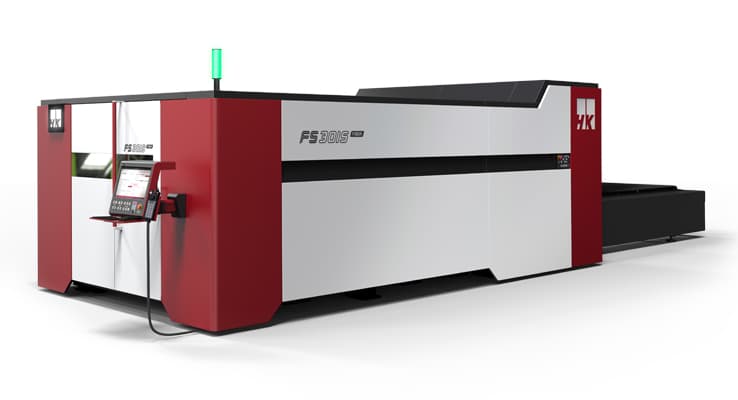

Metal fabrication shops and companies that manufacture customized metal parts can drastically improve their efficiency of production with our fiber laser cutting machines.

Triumph Laser comes with a computer as well as a foot switch, rotary and laser axes, 200mm lenses, laser goggles and a tool set for using the 30W desktop laser.

Fiber lasers have eliminated the need for mirrors or beam paths to align with them.

Gulf States Saw & Machine Co. (FM1212-50S) can engrave acrylics, brick, granite and marble, tile as well as aluminum, gold, silver stainless steel, brass or titanium.

1000W/2000W/3000W fiber laser cutter is used for cutting metal parts, arts, crafts, signs, signage, logos, letters, texts, kitchenware, and more sheet metal fabrication plans. Now the best fiber laser metal cutter for sale at cost price.

Fiber lasers have revolutionized the laser metal cutting industry thanks to their low maintenance costs and high cutting efficiency.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Marking and engraving are improved by high peak power and nanosecond pulses. The increased power and improved beam quality result in cleaner cut edges and faster cutting speeds. Fiber lasers are also used in material processing, telecommunications, spectroscopy, medicine, and directed energy weapons.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.