Robotic Coping Machines In Fortnite

A POWERFUL MEASURING and CLAMPING SYSTEMThe Voortman 808 has a powerful roller-feed measuring and clamping system. The fully automated measuring roller feed system saves time and money by not requiring a pusher or gripper before loading the next piece. This measuring and clamping system is more flexible because the maximum weight it can position is 15.000 kg/33.000 pounds.

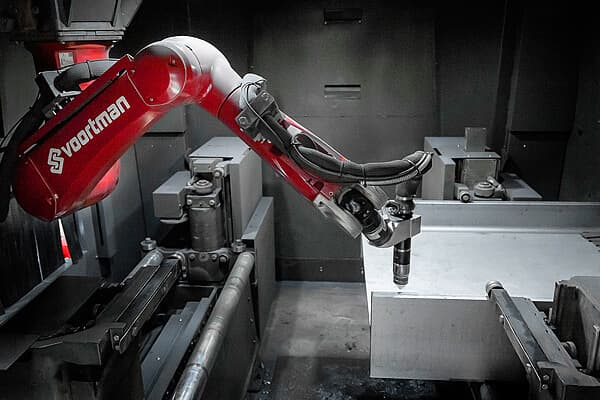

The top of the line coping/profiler makes 3D coping a breeze. These Robotic Coping & Profiling beams are reliable, as well as being able to cut saddles, chamlers or slots.