Torch

For steel fabrication, the steel beams, tubes, or pipes need to be coping. This allows them to fit in an assembly. These assemblies need to be able fit together odd-shaped or irregularly angled components, such as handrails. Car bumpers. Racecar roll cages. Coping allows any part to fit perfectly in its place regardless of its size or shape.

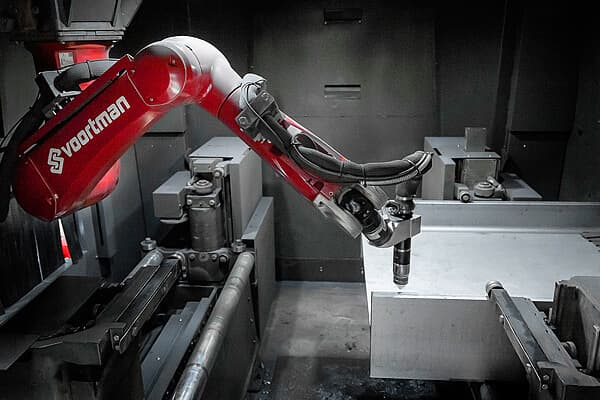

Our Robotic Coping & Profiling system can be used to automate the fabrication processes of metalwork manufacturers and fabricators. It can work with various angles, beam drill lines and hydraulic punches. This is a simple way to increase the efficiency of your fabrication process from zero to 100!