A Robotics Company

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.

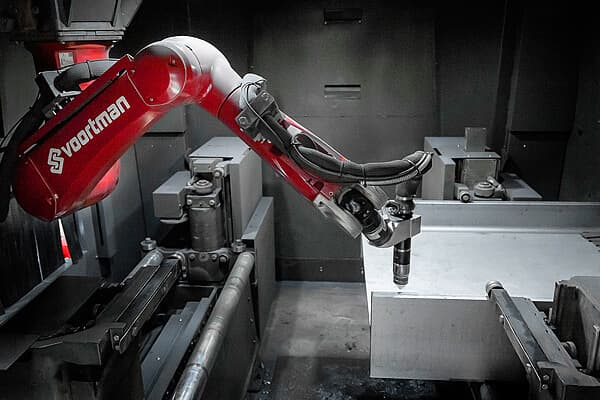

AFD CNC Flange and Plate Drilling Machines are capable of drilling from 6 to 80 mm to 1/4" to 3-1/8" thickness in its own work area. Material is driven onto the table with balls, and then fixed with hydraulic clamping Jaws. Material is positioned to the desired coordinates for drilling/marking/tapping by CNC program and then operation starts.