Robotic Coping Machines Episodes

In less than a day for your operator will learn how to use the PCR42 plasma cutter. The interface is very user-friendly and simple to use. If you should ever need assistance, Mac-Tech is ready to assist.

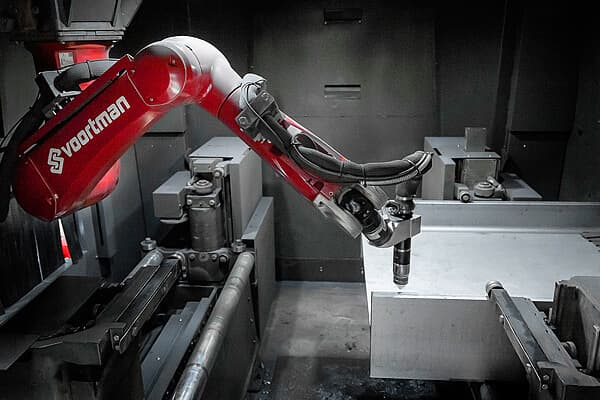

We care about making fabrication tasks smooth and efficient. Our Robotic coping/profile beam can be used to cut angles, channels, square tubes, and plates as well as pipes, T-bars, plates, and bulbs. Our Coping and profiling robots can perform a wide variety of functions on your pipe cuts/profiles. They are an efficient tooling system with unmatched quality. These outputs may be H, T beams, U or L channels.