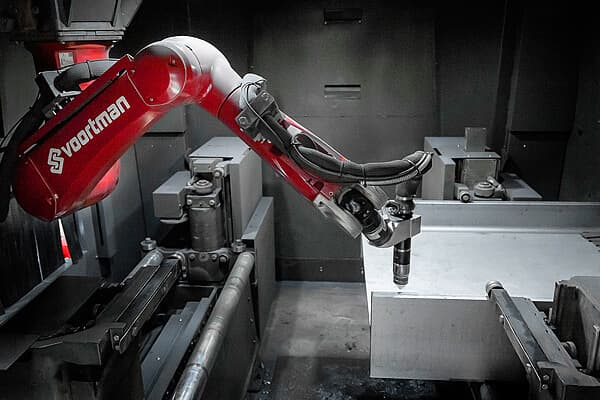

Robotic Coping Machines Best

Voortman V808, the most versatile and competitively priced robotic thermal cutter machine on the market, features 8-axis processing for wide profiles. The operating width of this machine is 1.250 mm (50") With the combination of the machine structure and robot flexibility, the machine can cut all 3D shapes possible and mark all 4 sides of your material. This system gives you the ability to create complex connections and copes and allows you to increase your production speed. Voortman's V808 is able to handle all your needs, including copes, bolt holes (slots), notches, bevels and weld prep.

Simply push the button and your production is done. After importing DSTV+ or industry standard DSTV files to the VACAM Software processing table, your operator will be able to fully concentrate on loading and unloading. It is not necessary to manually intervene in order to maintain the machine's production speed.