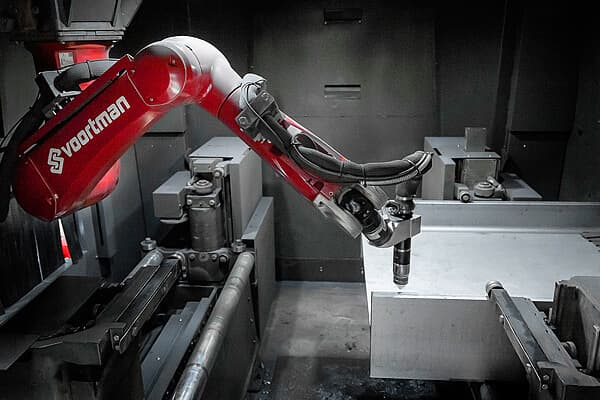

Robotic Coping Machine Labeling

Gulf States Saw & Machine Co. can assure you that your Robotic Coping and Profiling system is the best in the industry. It uses high-definition plasma technology to cut through a variety of metal profiles, including structural steel and other metal parts.

MSI, also known by Multi System Integration, allows you connect machines with cross transports as well as roller conveyors, product boxes, material buffers, and material sensor to fully automate the production line. MSI automatically distributes data to all of the machines in your production line.