Robot Coping Machine Kaise Banti Hai

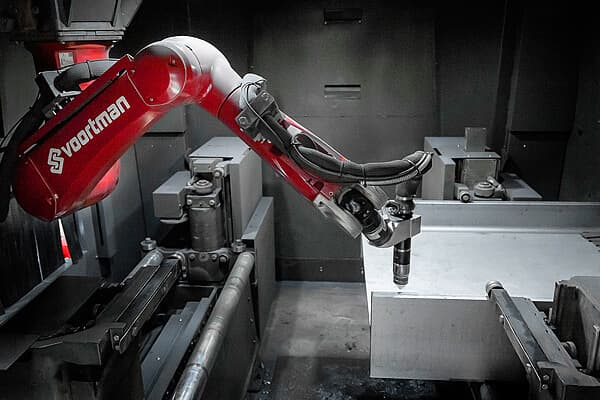

The V808 has an 8-axis, agile cutting robot that can reach and process all widths of profiles. Voortman added two additional axes to the six of the Panasonic robot's axes, giving the machine a wide reach that can be placed underneath the raw material. Voortman programmed the robot so that it moves in the most stable place, which improves the quality of the cutting.

In steel fabrication and other manufacturing processes, steel beams, tubes, and pipes often must undergo coping so that they fit properly within an assembly. Oftentimes, these assemblies must fit together odd-shaped components and irregular angles, such as handrails, car bumpers, and racecar roll cages. Coping enables all parts to fit perfectly into their setting, regardless of shape or size.