Robotic Coping Machines Last

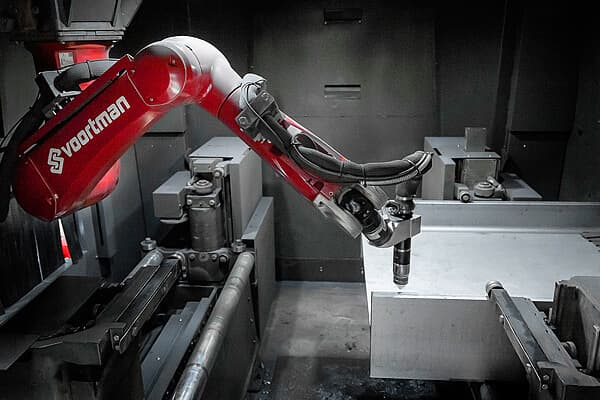

The PCR42 robotic Plasma Cutting Machine does beam coping. Notches, holes and welding preps are performed. Split beams can also be split. Scribes can be used to mark all four faces of H beams, channels, angles, HSS or plates.

The V808 rolling feed measurement and clamping device locks profiles in their exact positions and maintains alignment throughout processing. The most efficient positioning system, this fully automatic measuring roller-feed system saves hours per week by not requiring a pusher/gripper before loading the next piece. Voortman�s fully-automatic roller feed system operates within a standard range profile processing using Voortman�s automated cross transports. It has enough stability and support for proper positioning and processing beams up 15.000 kg (33,000 pounds).