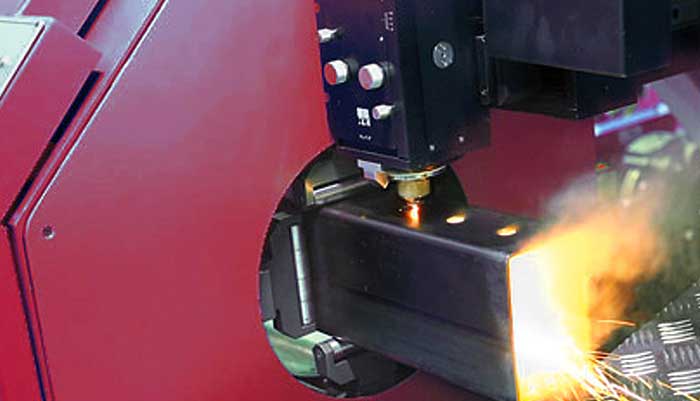

Youtube Laser Cutter

Lasertube lets you customize part designs to meet the needs of your customers.

Fabricators may think first of high speed cutting when thinking about fiber laser technology. It might be true that speed is relative when it involves tube cutting. It's about how long it takes to cut a tube to meet the specifications, not its actual speed.