Tube Laser Cutting Systems Yueming

Laser tube cutting at home doesn't have to be complicated or expensive. Students and engineers alike can cut like never seen before

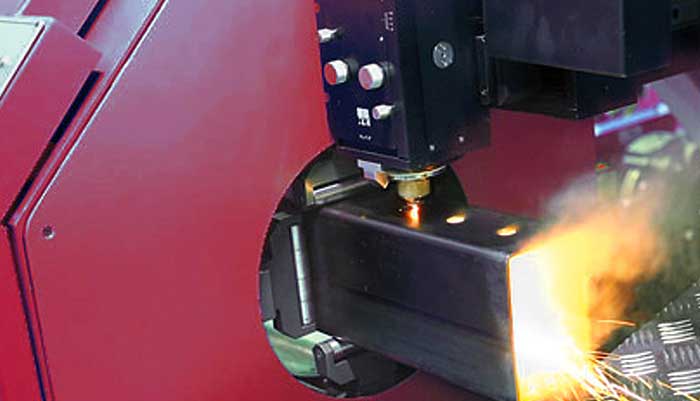

Many of Gulf States Saw & Machinery Co., Inc. tube laser-cutting machines incorporate intelligent machine functions, including monitoring, setup, and cutting functions. These functions automate machine operation, increasing efficiency and ease of use. These machines are ideal for many industries thanks to their tube and pipe lasers.