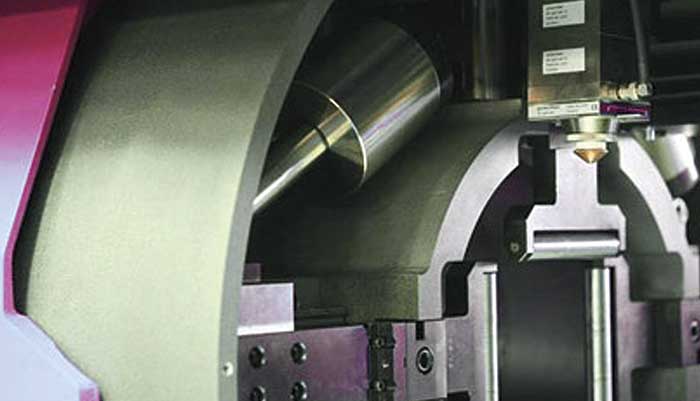

Adige Tube Laser

Whether it is the manufacture of specific equipment for gyms, or smaller, multifunctional exercise machines for domestic spaces, tubes are the fundamental building blocks. This is why tube processing technologies, such as bending and laser cutting, are so widely used in this sector.

When fabricators think about fiber laser cutting technology, they might think of high-speed cutting first. That might be true, but when it comes to tube cutting, speed is relative. It’s more about the time it takes to process a tube to meet specifications than actual cutting speed on the tube.