Tube Lasers Cutting Systems 2022

The subject of material loading and unloading automation is well established in sheet laser cutting with a multitude of solutions and complexity. In contrast, tube laser cutting systems equipped with vertical storage systems, for tubes and section bars, capable of handling bars automatically and allowing for unmanned production changes have only been available for a few years.

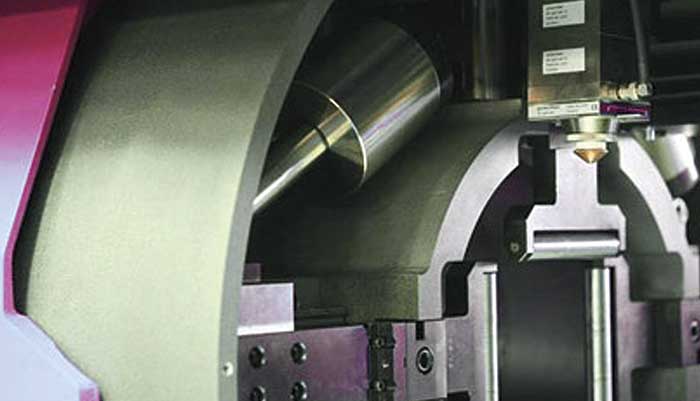

Some machinery manufacturers use cameras to check tubes. This is done in an effort to close the time gap. Cameras reduce the time required to check quality and reduce the number rotations. This ensures that the machine can retain its productivity and accuracy.