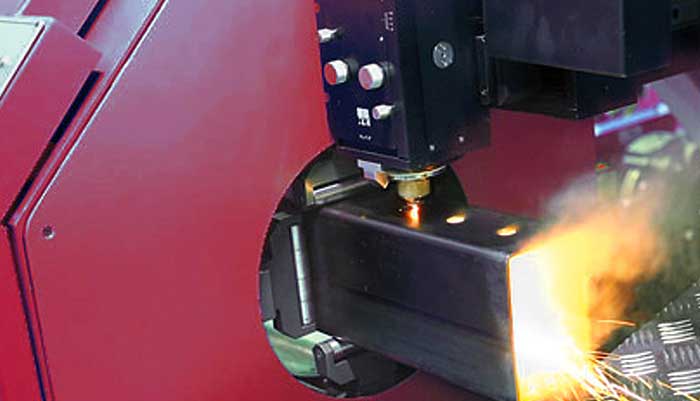

Mazak Tube Laser

Laser fabrication solutions that meet your exact needs are available. They also offer process efficiency and quality for metal and non-metal fabrication.

Micrometric Ltd uses a versatile Coherent StarCuttube laser cutting machine for speed and precision in manufacturing aerospace and medical products.