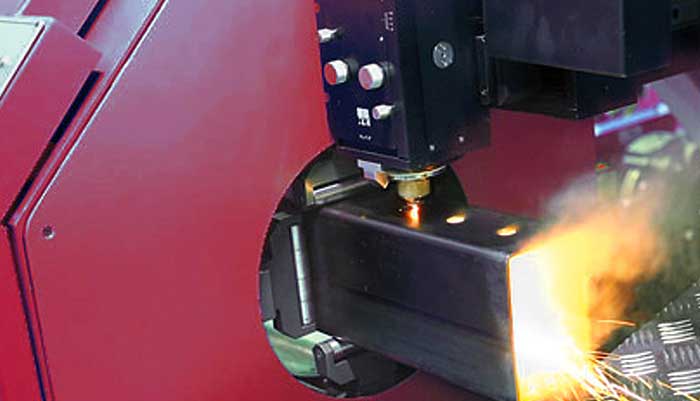

Tube Laser Cutting Systems 1kw

StarCut Tube SL combines an fs-laser to create complex metal shapes.

Access

In-house laser tube cutting does not have to be difficult or costly. Everybody, from engineers to students, can cut like never before

Every job shop has to have variety. Parts of different sizes may be obtained from the same tube. The machine must have the ability to load laser-cut parts, which can be as small at 2 inches. each other for a total length of 15 ft. It should also be able to load those parts without damaging them. This can sometimes be a problem with softer metals like aluminum.

Tube Lasers Cutting Systems New JerseyThe solution with the widest working range in tube laser cutting.Tubes up to Ø 9.45" (240 mm)3D cutting modeCO2 or fiber laser

How do you compensate for that? Traditionally, you are going to come down and touch the face with a sensor that marks the contact point. The tube is then rotated, and the opposite side of the tube is touched. That gives the control an idea of just how bowed the tube is. This method is accurate and can ensure those through-holes work out for the application. But keep in mind that each time a rotation of the tube occurs, the ability to deliver very high tolerances is reduced.

StarCut Tube SL combines an fs-laser to create complex metal shapes.

Save time and reduce number of components Metal structures and tubular frames can be made faster and more precisely. Completion of your part is possible in just one programming step, one machining step, or on one system.

There is a cutting technology that suits every need. Users have two options: CO2 laser cuttingsystems or fiber laser cutting systems, depending on the material to be cut and the level of productivity desired.

Gulf States Saw & Machinery Co., Inc. provides a wide range solutions when it comes processing tubes, pipe, and structural metal. Gulf States Saw & Machinery Co., Inc. tube lazers are not only superior in laser-cutting, but they also offer additional processing capabilities to benefit fabricators.

Fiber lasers achieve high cutting speeds in thin material thicknesses. Additionally they boast low power consumption while requiring little maintenance.The special properties of this laser cutting technology enable applications insteel, stainless steel, aluminum, and non-ferrous metals, such as copper andbrass.

The maintenance of a fiber laser is not as important. It doesn't need mirror cleaning or bellows checks like a CO2 Laser Cutting Machine. It does not need to be cooled with cold water, and air filters can be replaced regularly.

A laser tube cutter machine does not come with standard material towers. Bundle loaders are the most efficient option for tube material handling. They feed one tube from each bundle to the tube laser through a singularizing device. This type of feeding mechanism is not suitable for open profiles such as channels or angles, since they are interlocked while inside a bundle and can't be released easily. Step loaders are used for open profiles. They sequence each section into the machine one at a while maintaining the correct orientation.

The other factor to keep in mind is that the traditional method of checking for bows and twists in the tube can take up to five or seven seconds before cutting commences. With the traditional means of touch sensing, you have to trade productivity for accuracy. Again, in the age of fiber laser cutting, this can seem like a lifetime, but working with tube is not as simple as working with sheet metal.

Gulf States Saw & Machinery Co., Inc. can help you develop new designs that improve aesthetics, increase functionality, and bring new products to market quicker.