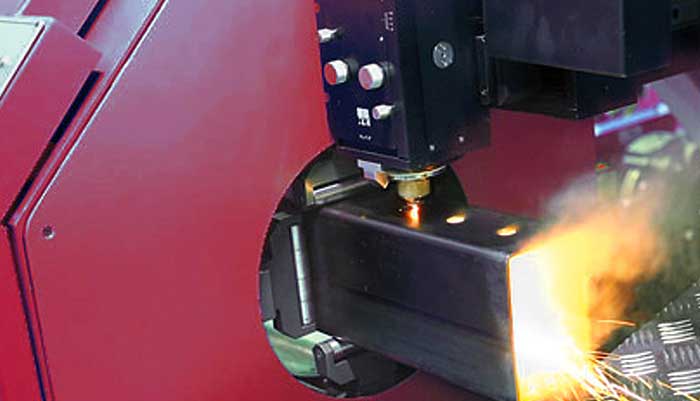

Reduce secondary operations: A tube-laser can cut a piece to size and add holes and other cutouts in one step. It eliminates the need to perform secondary actions or manually remove material. It is possible to keep tight tolerances even on complex fabrications. Parts can be made from one continuous piece. They are easy to put together and fit perfectly. We can also tube laser carbon, stainless steel, and aluminum.

Some things can be quite obvious. The fiber laser "generator", as it is called, is smaller than traditional CO2 resonators. The fiber laser is actually created by banks and modules of diodes. They can be assembled into a compact module with a power range of 600 to 1,500 watts. A number of modules are combined to make the final powered receiver, which is often the size of small filing cabinets. The light is amplified and channeled through fiber-optic cabling. The fiber-optic cable transmits the light exactly as it was before. This ensures that there is no loss of quality or power. Then, it is adjusted and focused according to the material being cut.