Gulf States Saw & Machinery Co., Inc. has a team of experts that can assist you in developing innovative designs to improve aesthetics, increase function, and get new products to the market faster.

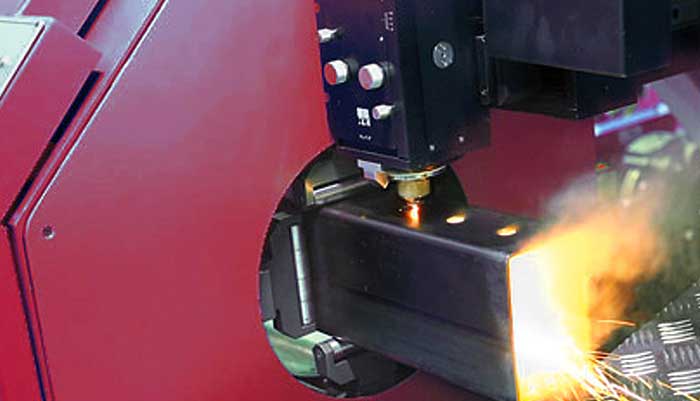

Tubes are very simple and do not require a powerful laser. Tube laser cutting machines require only 5 kW power, whereas flat sheet laser cutters can be powered by laser generators up to 12 kW. When cutting a tube, it is important to always think about the other side. A stronger laser would simply blow through the tube on the opposite side during cutting. You don't need to worry about the other side if you're processing a beam of a channel or a channel using the tube laser.