Why do vinegar soaks after CO2 laser

Another consideration in tube cutting is the weld seam. This material is roll-formed and welded together. This brings up two points that typically must be addressed:

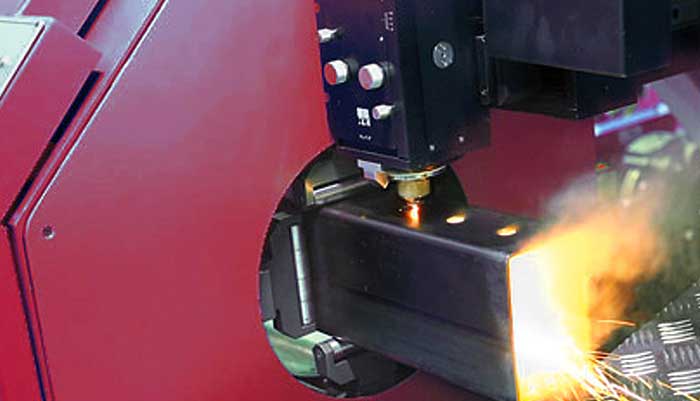

Even for XXL tubes, this machine is designed for maximum productivity. This machine is robust and solid-state laser capable of processing tubes and profiles of a wide variety of materials and wall thicknesses.