Range

Imagine that you have to position a through-hole on top of a tube. It must be centered on the tube's actual dimension. It will be more difficult to center the tube if it is bent. This is the reality of tube fabrication.

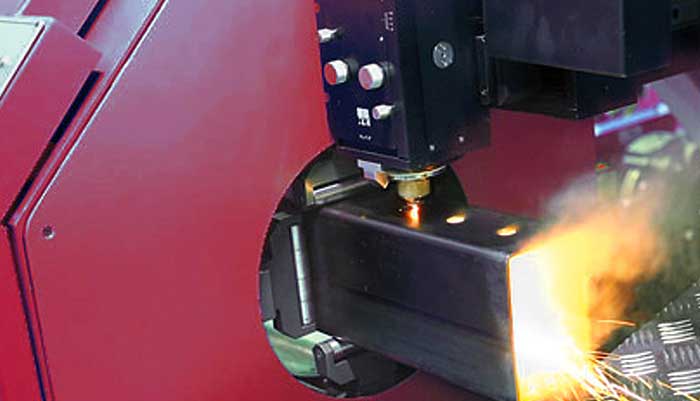

This is the easiest way to enter tube laser cutting. Tubes upto O 4,72" (120mm)2D CutFiber laser