Fiber lasers are nearly maintenance-free and demonstrate superior wall plug efficiency compared to traditional CO2 Laser cutting machines. They can also be used for precise cutting of reflective materials. They are faster than CO2 when cutting certain thicknesses of steel. The speed of cutting tube is relative. Real time savings can be achieved by speeding up processing times for the tube and creating finished parts.

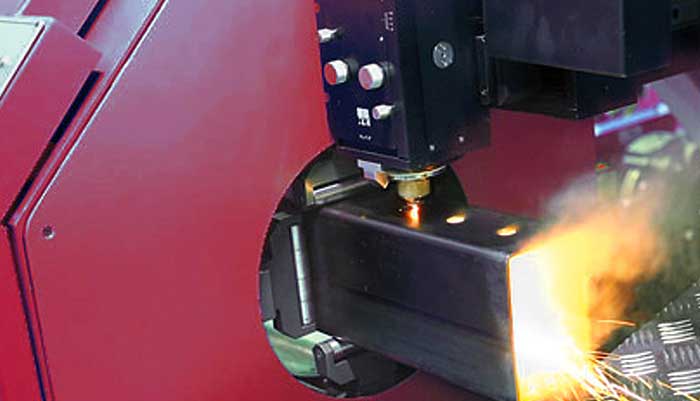

A tube's very nature prevents the use of high-powered lasers. Flat sheet laser cutting machines can now be equipped with laser generators that are as powerful as 12kW. Tube laser cutting machines, however, only require 5kW. You must always consider the side you are cutting when you work with a tube. A stronger laser will simply cut through the tube from the opposite end. (Officially, you don't have any need to worry if you are cutting a beam or channel with the tube laser.