Tube Lasers Cutting Systems York Pa

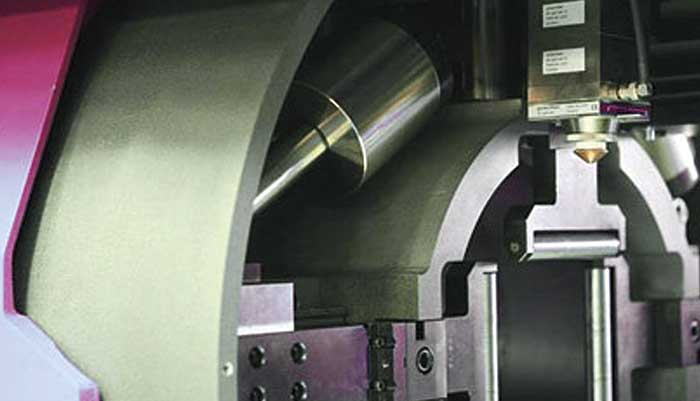

The fiber solution for large diameter tubes and profiles.Tubes up to � 14" (355 mm)3D cutting modeFiber laser

StarCut Tube L 600 has a choice of three laser options: a fiber laser or a USP. StarCut Tube SL has the smallest footprint of any model on the market.