Laser Tube Cutting Machine Price

Laser cutting machines that cut sheet metal can turn a sheet into a sheet in seconds. A laser tube cutter machine can do the same thing, but it's quite different in how it's done.

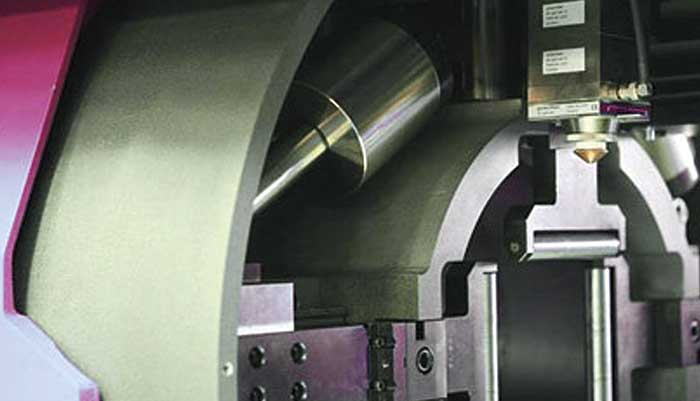

Tubes are and will continue to be used throughout the entire industry, including in system and mechanical engineering as well as furniture construction. New design possibilities have been opened by lasers. This means that more and more designers are utilizing the benefits of laser-cut tube and profile cutting, which is driving up demand. TruLaser Tube machines offer all-round solutions in the field of laser tube cutters.