Angle Iron

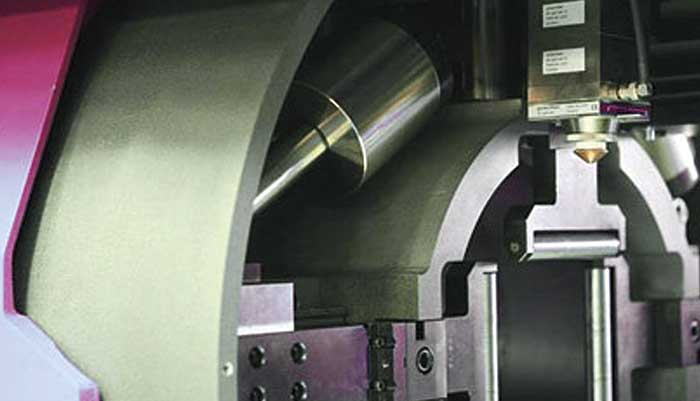

The fully-automatic solution for maximum productivity, fast production changes and high quality. Tube O Range min. 0.47" (12 mm) - max. 6" (152.4 mm)3D cutting modeFiber laser

Machine manufacturers have begun using cameras to perform tube inspections. They can reduce the time it takes to inspect quality tubes and also reduce the amount of rotations needed. This allows for both productivity and accuracy to be maintained.