Tube Laser Cutting Systems Qatar

Fiber lasers can be used to cut reflective materials and provide precise cutting. They are almost maintenance-free. They can also cut certain thicknesses of metal faster than CO2 lasers. But speed is only relative when cutting tube. Speeding up the process of cutting tube and producing finished products can make time savings.

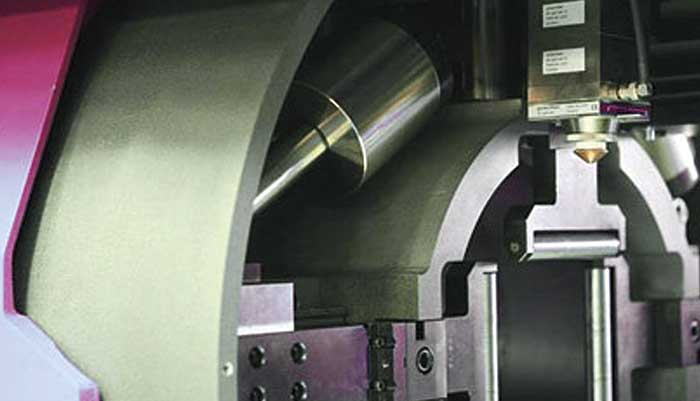

The ability to choose between 2D and 3D laser cutting technology opensup the possibility of individually customized and precise cutting of parts in avery wide variety: tubes with round, square, and rectangular shapes as well asprofiles with diverse open cross-sections (for example H, L, T, and Ucross-sections). In addition tostraight cutting edges, the 3D technology also enables bevel cuts up to 45degrees. This versatility eliminates the need for costlymilling, drilling, punching, or sawing processes.