3d Tube Laser Cutting

The FABRICATOR is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The FABRICATOR has served the industry since 1970.

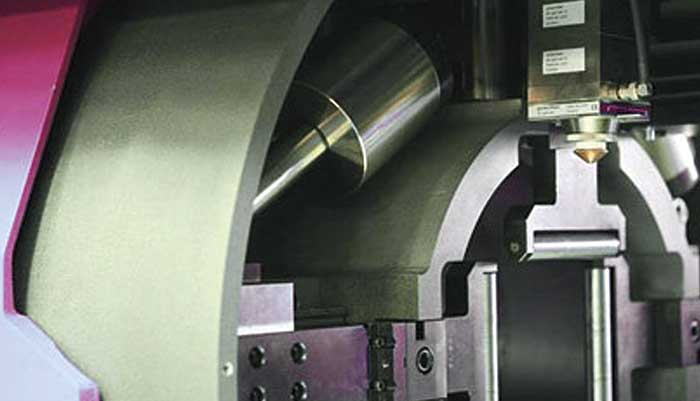

StarCut Tube SL, a turnkey machine, includes an fs laser. It is perfect for laser cutting complex shapes like thrombectomy stent retrievers.