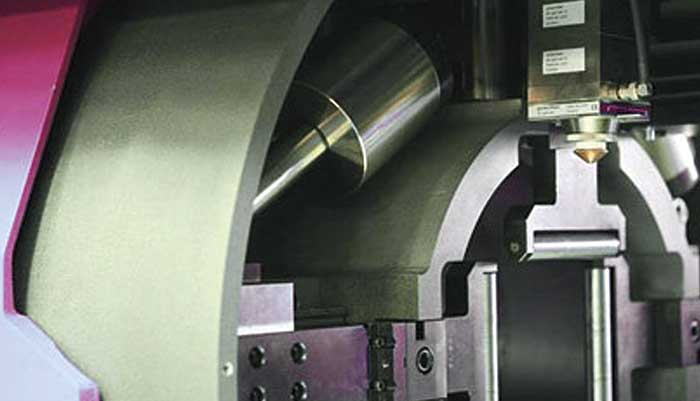

Tube Laser Cutting Systems 50w

A CO2 laser is more efficient than a fiber one because it requires less power to create. This means that large chillers for CO2 lasers will require more overall power. With a wall plug efficiency greater than 40%, the fiber laser resonance uses less power and takes up less space.

Tube extensions are available for loading tube stock to the maximum length of 80", or 6'8". The maximum part size is 52".