Can you laser cut a cylinder

Tubes are the basic building blocks of any equipment, no matter how small or multifunctional they may be for home use. This is why tubes are used so extensively in this sector, including laser cutting and bending.

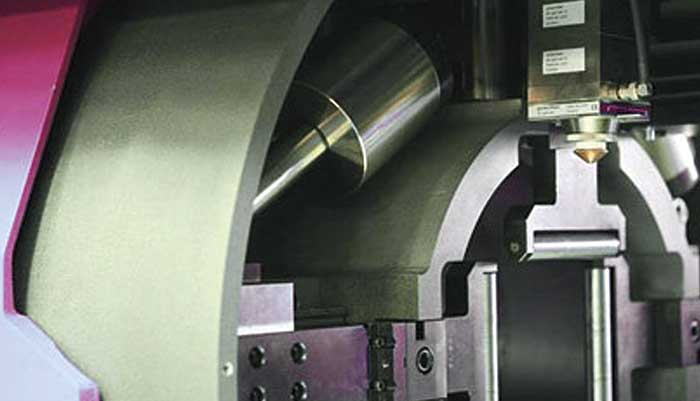

ExactCut 430, a laser cutting machine for precision processing of thin and large metals and all alloys, brittle material like sapphire or PCD, is available.