Fiber Laser Cut

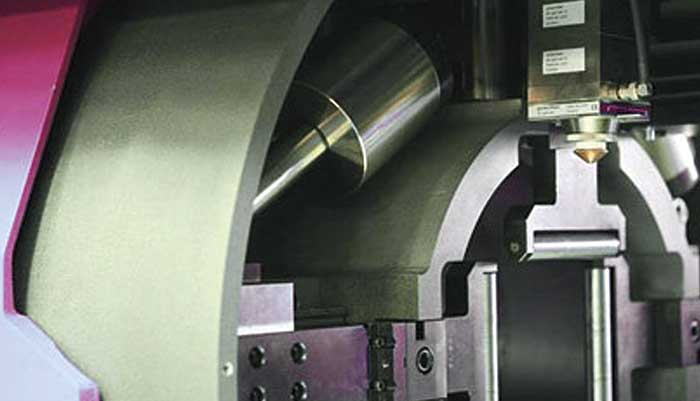

Learn how the Coherent StarCut Tube and StarFiber laser-powered cutting machines helped NPX Medical gain a competitive edge in stent manufacturing and more.

It is important to remember that traditional ways of checking for twists and bows can take up five or seven seconds, before cutting can begin. Touch sensing can only be used for precision. It can seem that this is all a lot, but it's not the same as working with sheetmetal.