Tube Laser Cutting Systems Repair Near Me

Tubes are essential building blocks, whether it's the production of equipment for gyms or small, multifunctional exercise machines that can be used in domestic spaces. Tube processing technologies such as laser cutting and bending are widely used in this industry.

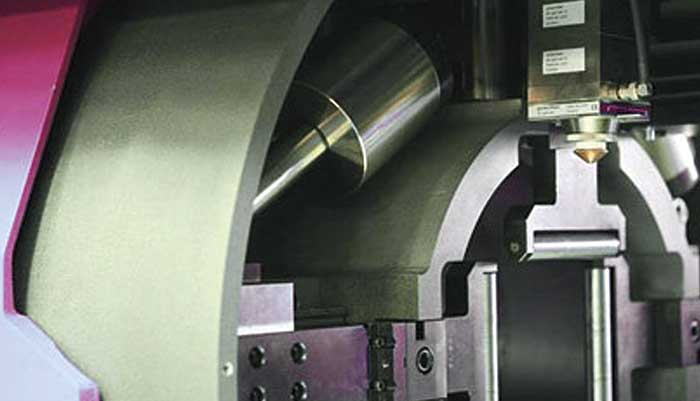

Motion Dynamics is a leader in the manufacture of neuro-sub-assemblies. This includes steerable catheters, "pull-wire" assemblies and other neurological components. We use our StarCut Tube machines to precisely cut key components.