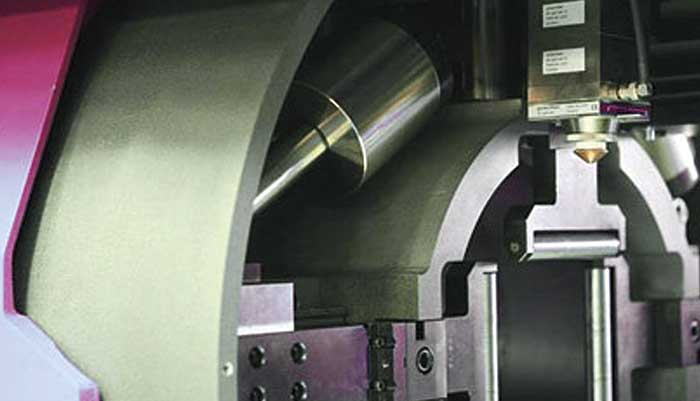

Pipes

When making fitness equipment, the most important components are durability, usability, compactness, and design.

Keep in mind that there is no such thing as a perfect tube. They have bows. Weld seams can protrude not only on the exterior but also the interior of the tube. It�s a real challenge to process this material consistently and rapidly when such inconsistencies exist from one product run to another.