Fiber Laser Cutting Machine Europe

Boss Laser sends FM-Desktop pre-assembled. They also provide on-location technical support for their customers.

It is free software that you can use on Microsoft Windows XP and Windows 2000.

Advanced Series

MCWlaser PRO's Z-axis can be adjusted manually by using a control wheels. Unfortunately, XY-axes aren't adjustable.

This fiber laser can provide a repeatable precision up to +-0.0001" and a beam strength of less than 1 M2.

Do you have an idea to DIY or buy an affordable fiber laser cutting machine for custom metal fabrication with laser powers of 1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, or 40000W? Review 2022 best fiber laser cutter buyer's guide for machinists, operators and beginners, we'll offer you 2022 cheapest fiber laser cutting systems for stainless steel, mild steel, carbon steel, galvanized steel, tool steel, titanium, aluminum, iron, copper, brass, and alloy with expert customer service to fit your custom metal cutting plans, ideas or projects in hobby use, home shop, small business, commercial use, and industrial manufacturing.

The enclosure has a motorized door. It works when using FSL Muse Pandora in a desktop configuration.

Boss Laser sends FM-Desktop pre-assembled. They also provide on-location technical support for their customers.

It is free software that you can use on Microsoft Windows XP and Windows 2000.

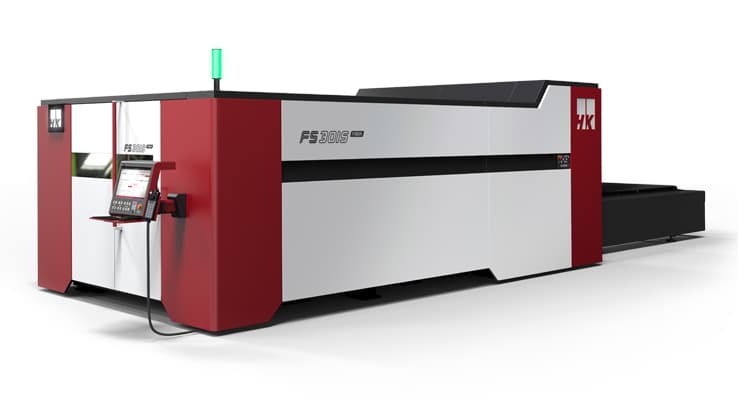

The REGIUS 3015 AJ fiber laser is the pinnacle in speed, accuracy, and machine utilization. The high-speed 3-axis linear drive system combined with AMADA�s original Variable Beam Control Technology allows the REGIUS to provide unmatched productivity while processing different materials. The REGIUS is also packed with features to support autonomous operation such as lens monitoring, collision recovery, and automatic nozzle change & centering.

MCWlaser PRO comes with an adjustable Z-axis. This can be moved manually using a wheel. Unfortunately, the XY or Y axes cannot adjusted.

Engraving applications are where a fiber laser shines. It can mark, etch, and engrave on metals at an incredible speed.

Metal fabrication shops and companies that manufacture customized metal parts can drastically improve their efficiency of production with our fiber laser cutting machines.

The laser beam is then amplified using an optical fiber and fed to a cutting head.

It is suitable for engraving on metals and can engrave at a maximum speed 11.760 ipm. It can mark complex fonts and images on both smooth and uneven metal parts.

You don't need to worry about leftover cutting residue such as dross if you can set the parameters correctly in laser cutting.

Getting into the details of the operation cost of both laser and plasma is complicated. So I will write about that in another post.

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

What Materials Can Be Cut With A Fiber Laser? A fiber laser cutting machine can cut sheet metal such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Fiber lasers outperform CO2 lasers in cutting reflective materials.