Dne

The SR-F series from Mitsubishi features a 3m by 1.5m compact footprint and offers the user diverse functionality.

Co2 Lasers

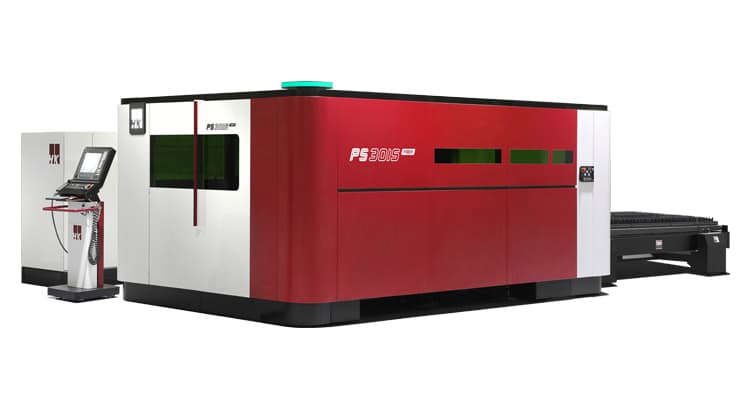

Our machines are capable of cutting steel, brass, aluminum and stainless steel without fear of back reflections damaging the machine. By using these fiber laser machines, you�ll reduce your maintenance requirements and cut your operating costs considerably.

Triumph Laser supplies EZCAD2.0 software to control their desktop laser engraver. EZCAD2.0 is capable of creating basic shapes as well as text.

The support column, or Z-axis, holds the laser arm. The height adjustment knob allows you to adjust the laser focal point by moving Z-axis.

People who use plasma always tell me they must watch over their plasma cutter. They say the plasma machine can start cutting wrong or get out of control (imagine seeing a plasma machine head swirling around in crazy motion?)

The SR-F series from Mitsubishi features a 3m by 1.5m compact footprint and offers the user diverse functionality.

Triumph's 30W desktop fiber-laser can engrave on aluminum and gold, silver and stainless steel. It also works with some plastic-like materials for machine parts and tools.

Raycus 50W laser fiber can etch aluminum at a 90 degree angle and mark it with 100% laser power.

FSL Muse Pandora's 20W version can deep engrave sterling at a speed up to 708 ipm using 100% of its laser power.

A fiber laser cutter needs regular inspection and maintenance. If there is deformation or other forms, you should know that the laser cutting head has been damaged a little at this time, and you need to replace it. Failure to replace will affect the cutting quality and increase the cost, and some products may need to be reprocessed to reduce production efficiency.

This fiber laser can give a repetitive precision of �0.0001" with a beam quality of less than 1.1 M2.

Some PVC-based acrylic releases toxic fumes when lasered. Therefore, it is better to check the chemical compositions of the materials you plan to engrave.

With the rise of optical fibers, the need for mirrors and beam paths for alignment has also been eliminated in a fiber laser.

Additionally, laser cutting can be done correctly so that you don't have any leftover cutting residue.

Maximum material cutting thicknesses by 1000W fiber laser cutting machine: Carbon steel has a maximum thickness of 10mm; stainless steel has a maximum thickness of 5mm; aluminum plate has a maximum thickness of 3mm; and copper plate has a maximum thickness of 3mm.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

The wavelength is the primary distinction that determines the types of materials that each laser can process. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have many advantages over CO2 lasers in general.