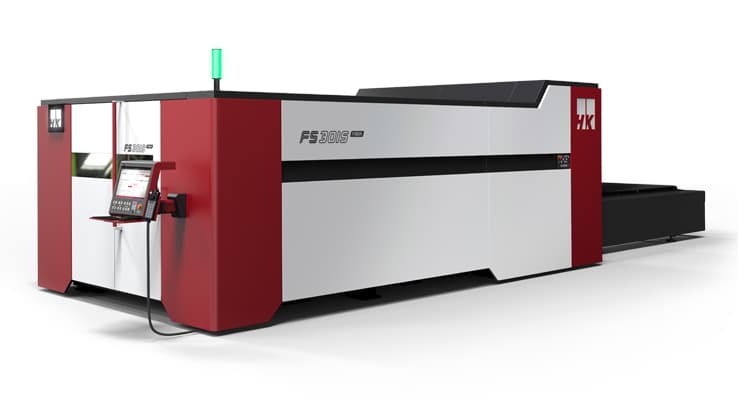

Bodor Laser Cutter

Laser cutting machines are able to cut metal with great precision. This is the main reason they are so popular. Plasma cutters can be cut with 2X greater accuracy than laser cutting machines. Plasma lasers can be used to cut metals with a precision of 0.1mm, or.004 inches. Laser cutters can cut metals at a precision of.05mm to.002 inches.

Plasma can cut anything that's conductive. This basically means that it can cut all types of metals. Plasma can cut any reflective metal, such as brass, copper and aluminum (which laser machines cannot do).