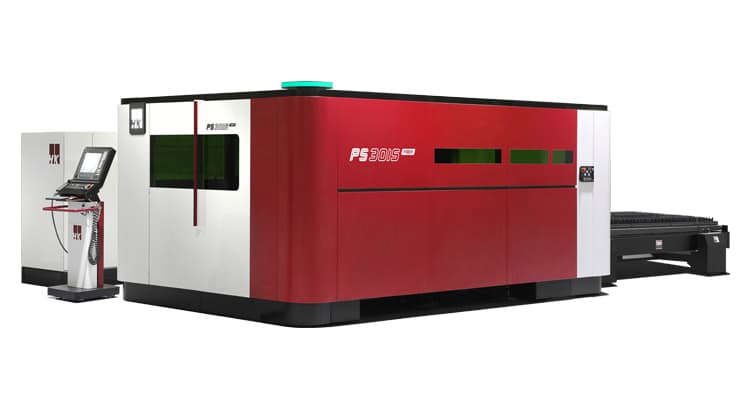

Fiber Laser Machines

For the most demanding fabrication requirements, with thick materials and no room for error, our CO2 lasers can give your products and your business a serious edge.

Unlike CO2 lasers, fiber lasers consume much less energy and operate at a shorter wavelength ranging between 780 nm and 2200 nm, giving a much higher absorption rate.