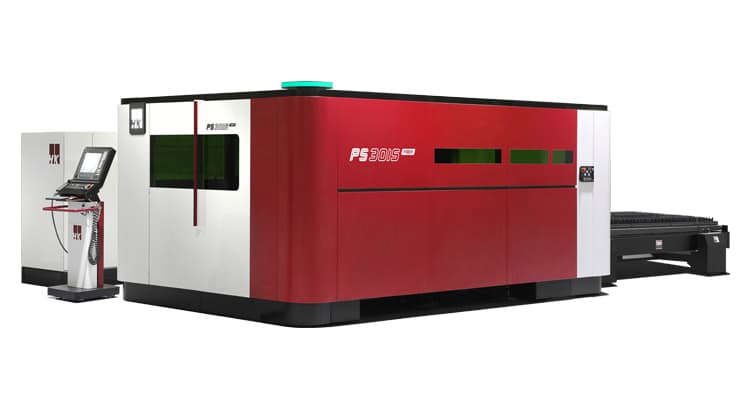

Fiber Laser Machinery Zymt

It can engrave on metals at a maximum speed up to 11,760 ipm. It can mark images and fonts on metal surfaces, both smooth and rough.

Make sure you buy safety glasses that block the laser light of 1064 nm when buying safety glasses for this machine.