Fiber Laser Machinery 60

Finally, the laser beam has been shaped at cutting head with focus lenses. It is projected onto work materials.

Auto-focus automatically adjusts laser head position on the Z-axis based on data received from the 3D cam.

Fiber Laser Machine Manufacturers In India

MOPA fiber laser is a special type of fiber laser that allows for greater control over the pulse width and frequency parameters. This laser can be used to color laser engravings on metals.

Boss Laser provides the CorelDRAW 2020 version as an add-on at a discounted rate with the FM-Desktop engraver machine.

You should be aware that the fiber laser will have limitations on the size of your work area and the materials you can cut.

Raycus is a popular laser source brand. This laser can be used by many different laser cutter, and engraver manufacturer. Raycus will appear in various places on the catalogs and websites of laser manufacturers. It simply means that all these machines have a Raycus Fiber Laser Technologies Co. Ltd. as their laser source.

Finally, the laser beam has been shaped at cutting head with focus lenses. It is projected onto work materials.

Auto-focus automatically adjusts laser head position on the Z-axis based on data received from the 3D cam.

Boss Laser will pre-assemble your FM-Desktop. They also offer technical support on-site to customers.

Laser machines can cut any material. The type of laser machine you use will determine the material that can be cut. A CO2 laser machine is unable to cut through reflective materials like brass, copper, and aluminum. However, they can cut through nonmetallic material like wood and polymer.

FM-Desktop has the ability to engrave acrylic, plastics (brick, PVC), granite, marble and tile.

Fiber lasers use much less energy than CO2 lasers. They operate at shorter wavelengths (780 nm to 2200 nm) and have a much higher absorption.

For after-sales services, you can contact them through phone, e-mail, or through their social media handles.

MCWlaserPRO can be purchased in half pre-assembled. First, fix the vertical columns connecting the laser source module and the laser engraver modules.

High precision lenses are used to collimate and increase the energy density in laser machines equipped with fiber laser sources.

Fiber lasers use solid-state lasers extensively in laser engraving and marking machines. The difference between a Fiber laser and a Co2 laser is in their ability laser cut sheet metal.

Options for payment The average laser can cost between $50,000 and $250,000, making it a significant asset to a business.

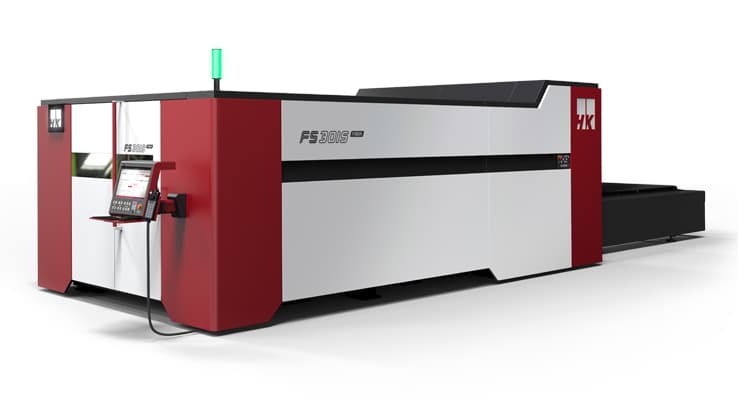

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.