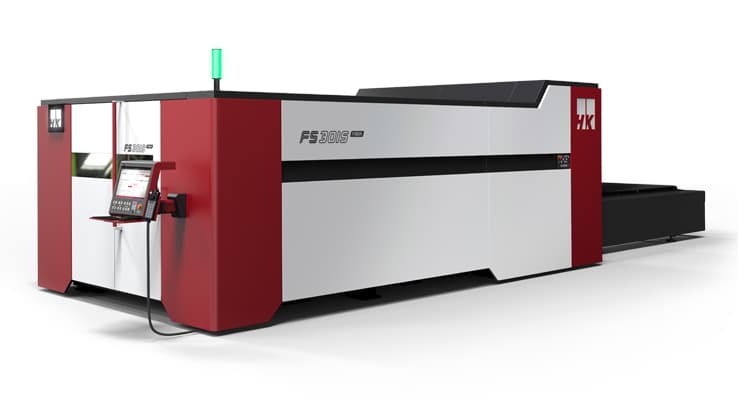

Fiber Laser Cutting Machine Table

Our machines are capable to cut steel, brass or aluminum with no back reflections. These fiber laser machine will significantly reduce your maintenance requirements as well as your operating cost.

It will be able to run at the recommended speeds and power rates for steel, aluminum, black acrylic and lexan as well as granite and other materials.