Technology

The laser beam generated is amplified, then fed to the cutting head via a flexible optical fibre.

You can make them work at an extremely high speed by adding a galvohead. Galvo heads can be found in portable laser engravers.

Fiber Laser Machinery 980nm

MCWlaser PRO's Z-axis can be adjusted manually by using a control wheels. Unfortunately, XY-axes aren't adjustable.

This fiber laser can provide a repeatable precision up to +-0.0001" and a beam strength of less than 1 M2.

Boss Laser sends FM-Desktop pre-assembled. They also provide on-location technical support for their customers.

It is free software that you can use on Microsoft Windows XP and Windows 2000.

The laser beam generated is amplified, then fed to the cutting head via a flexible optical fibre.

You can make them work at an extremely high speed by adding a galvohead. Galvo heads can be found in portable laser engravers.

The laser beam is then amplified using an optical fiber and fed to a cutting head.

It is suitable for engraving on metals and can engrave at a maximum speed 11.760 ipm. It can mark complex fonts and images on both smooth and uneven metal parts.

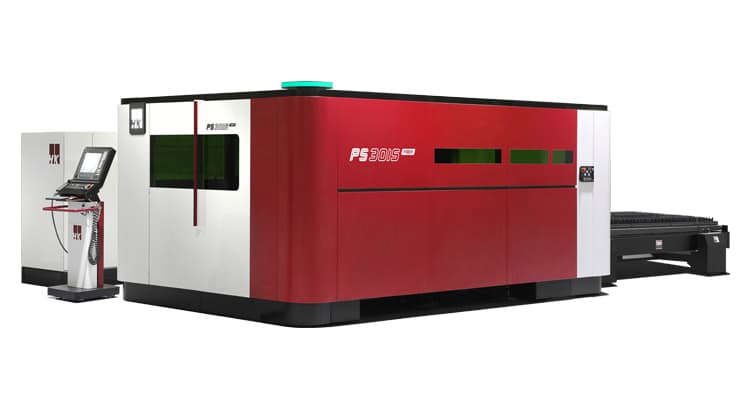

Do you have an idea to DIY or buy an affordable fiber laser cutting machine for custom metal fabrication with laser powers of 1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, or 40000W? Review 2022 best fiber laser cutter buyer's guide for machinists, operators and beginners, we'll offer you 2022 cheapest fiber laser cutting systems for stainless steel, mild steel, carbon steel, galvanized steel, tool steel, titanium, aluminum, iron, copper, brass, and alloy with expert customer service to fit your custom metal cutting plans, ideas or projects in hobby use, home shop, small business, commercial use, and industrial manufacturing.

The enclosure has a motorized door. It works when using FSL Muse Pandora in a desktop configuration.

Engraving applications are where a fiber laser shines. It can mark, etch, and engrave on metals at an incredible speed.

Metal fabrication shops and companies that manufacture customized metal parts can drastically improve their efficiency of production with our fiber laser cutting machines.

You don't need to worry about leftover cutting residue such as dross if you can set the parameters correctly in laser cutting.

Getting into the details of the operation cost of both laser and plasma is complicated. So I will write about that in another post.

Marking and engraving are improved by high peak power and nanosecond pulses. The increased power and improved beam quality result in cleaner cut edges and faster cutting speeds. Fiber lasers are also used in material processing, telecommunications, spectroscopy, medicine, and directed energy weapons.