What is better a CO2 laser or a fiber laser

When you need to reproduce or alter the dimensions of a piece that�s already been made, the best place to start is with the piece itself. That, and a high-accuracy 2D or 3D inspection machine.

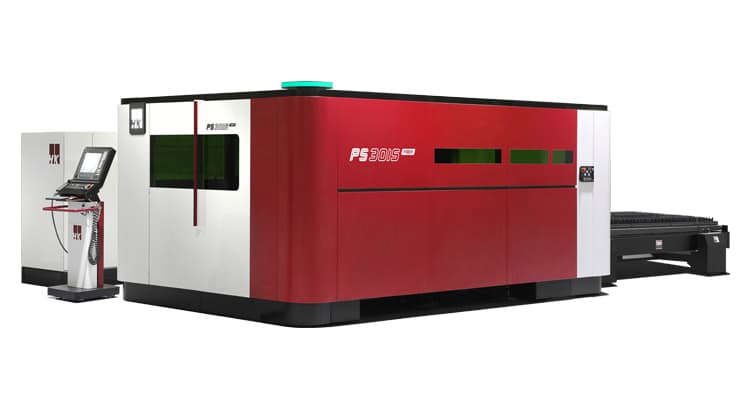

Fiber laser is a new type of laser cutting technology in the world that outputs a high-energy density laser beam and gathers it on the surface of the part to instantly melt and vaporize the area on the part irradiated by the ultra-fine focus spot and move the spot through the CNC controller. Irradiate the position to realize automatic cutting. Compared with the bulky gas laser and solid laser, it has obvious advantages. It has gradually developed into an important candidate in the fields of high-precision laser cutting, lidar systems, space technology, laser medicine and other applications.